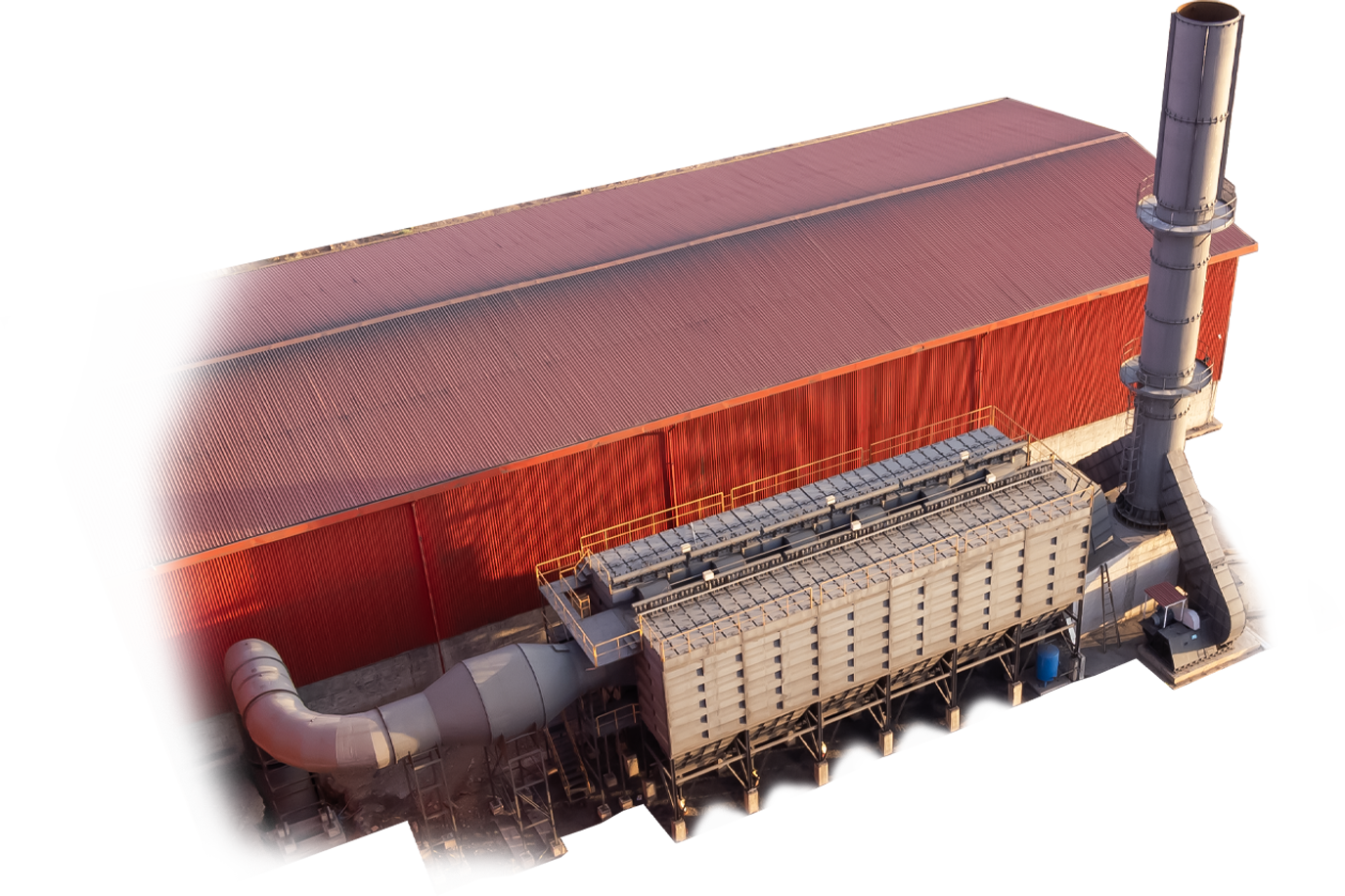

An industrial dust collector, also known as a bag filter, is a device designed to capture and eliminate dust, particles, and airborne pollutants from air or gas streams using its fabric filter bags. Bag filters play a vital role across various industries, including cement plants, asphalt production, steel smelting, foundries, and more.

Types of Industrial Dust Collection Systems

Industrial dust collection systems come in various types, each designed to suit specific operational needs and environmental conditions. The main categories include:

- Shaking Dust Collector: Utilizes mechanical shaking to dislodge accumulated dust from filter bags.

- Reverse Air Dust Collector: Employs a reverse airflow to clean the filters without interrupting operation.

- Pulse Jet Dust Collector: Uses high-pressure air pulses to rapidly clean filter bags, ensuring continuous performance.

- Sonic Dust Collector: Applies sound waves to vibrate and release dust particles from the filters.

- Cartridge Dust Collector: Features compact cartridges with pleated filters, offering high filtration efficiency in limited spaces.

Technical Specifications of the Industrial Dust Collection System

The system comprises multiple fabric filter bags designed to capture solid particles and dust. The number of these bags varies depending on the volume and type of pollutants, typically ranging from 3 to 10 or more. Most bag filters used in dust collection units can withstand temperatures up to 120°C. However, by replacing the bag material with polyamide or fiberglass, this tolerance can be increased to as much as 260°C. Additionally, bag filters can be equipped with a PLC control system for automated operation.

Technical Specifications of Bag Filter Materials

Bag filters for dust collection systems are available in various materials, including polyester, Nomex, and others. While polyester bags are commonly used in most systems, the selection of material should be based on the physical and chemical properties of the pollutants specific to the industry. The following table outlines the technical specifications of bag filters made from different materials:

Introduction to Types of Industrial Dust Collectors

Industrial dust collectors are designed to trap solid particles present in incoming air using fabric filter bags. Over time, a layer of dust accumulates on the surface of these bags. Various methods exist for cleaning the filter bags of dust particles, and based on these methods, different types of dust collectors have been classified.

Mechanical Shaking Dust Collector

In this type of dust collector, the filter bags are attached to a metal plate that is horizontally shaken by a motor. This shaking action causes the dust to be dislodged from the bags and expelled through the open bottom section. The efficiency and speed of the cleaning process in mechanical shaking dust collectors depend on several factors, including:

- The material and design of the filter bags

- The physical properties of the dust particles

- The amplitude and frequency of the shaking motion

Due to the low air-to-cloth ratio in mechanical shaking systems, a larger number of filter bags and more space are required to achieve effective cleaning.

Reverse Air Industrial Dust Collector

In the reverse air method, dust collector filters are attached to a metal rod on one end and suspended from the other. As contaminated air enters the bags, airborne particles accumulate on their surface. Subsequently, clean air is introduced in the reverse direction, causing the bags to collapse and deform, which in turn dislodges the dust layer from the inner walls. Similar to mechanical shaking systems, reverse air dust collectors require substantial space for installation.

Sonic Industrial Dust Collector

The sonic dust collector operates by generating low-frequency sound waves through an acoustic blower, which causes the filter bags to vibrate. These vibrations effectively clean the bags by dislodging accumulated dust. This method is less commonly used compared to others and is typically employed in combination with other techniques to enhance performance.

Cartridge Industrial Dust Collector

In this type of dust collector, the filters are pleated and mounted on a wire frame. This design increases the filtration surface area, allowing for greater dust capture. Cartridge dust collectors are available in two models: single-cartridge and intermittent. In the single-cartridge model, the cartridge must be removed and cleaned after dust accumulation. In contrast, the intermittent model integrates pulse jet technology, enabling in-place cleaning of the filter without the need for cartridge removal each time.

Operating Mechanism of an Industrial Dust Collector

Contaminated air or gas is drawn into the dust collector via a suction fan and directed toward the filter bags. Dust particles and airborne contaminants are trapped on the surface of these bags, forming a layer over time. At scheduled intervals, this layer is dislodged using various cleaning methods such as mechanical shaking, reverse air, or pulse jet compressed air. Clean air then passes through the bags and exits the system, while the separated dust particles fall into the hopper of the bag filter for collection and disposal.

Key Considerations When Purchasing a Bag Filter or Selecting a Dust Collector

When choosing an industrial bag filter system, it is essential to evaluate the following factors to ensure optimal performance and compatibility with operational requirements:

- Suitability for the Industry and Installation Site: Assess whether the system aligns with the specific industrial application and environmental conditions of the intended location.

- Dust Collection Capability: Examine the system’s effectiveness in capturing dust particles of varying shapes, sizes, and volumes.

- Resistance to Toxic or Chemically Reactive Dust: Ensure the dust collector can withstand exposure to hazardous or chemically active particulates.

- Durability of Filter Bags Under High Temperature or Humidity: Verify the filter bags’ resilience in extreme thermal or moisture conditions.

- Air Permeability of Filter Fabric: Evaluate the fabric’s capacity to allow adequate airflow while maintaining filtration efficiency.

- Dimensions and Installation Requirements: Consider the physical size of the unit and the necessary infrastructure for proper installation.

- Installation, Maintenance, and Operating Costs: Factor in the total cost of ownership, including setup, servicing, and upkeep.

- Build Quality and Compliance: Inspect the construction quality, material of the filter bags, suction performance, and adherence to industry standards.

Applications of Industrial Dust Collectors

Bag filter dust collectors are utilized in any industry where the collection of dust and production-related pollutants is essential. Their installation is considered critical in the following sectors:

- Asphalt Plants

- Mineral Processing Facilities

- Chemical Manufacturing Plants

- Cement Factories

- Iron and Metal Smelting Furnaces

- Pharmaceutical Production Units

- Food Processing Industries

These systems play a vital role in maintaining air quality, ensuring regulatory compliance, and protecting both equipment and personnel from harmful airborne contaminants.