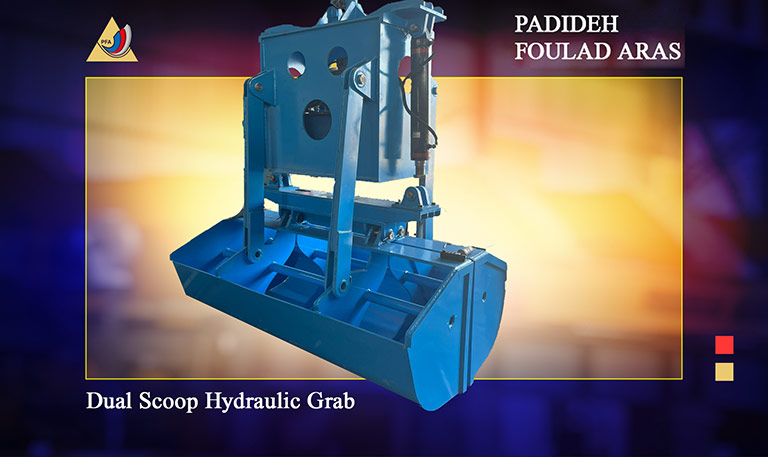

Dual Scoop Hydraulic Grab

Dual Scoop Hydraulic Grab (Clamshell Grab) The Dual Scoop Hydraulic Grab, also known as the Clamshell Grab, is a powerful tool designed for handling bulk and granular materials. This device consists of two symmetrical, movable jaws (or buckets) that open and close hydraulically. Applications: The fully enclosed structure of this grab makes it ideal for [...]

CCM Mould

Continuous casting plays a vital role in iron and steel production, with the continuous casting crystallizer recognized as the “heart” of the casting machine. Molten steel solidifies through the cooling process within the crystallizer. To prevent the cast billet from adhering to the copper wall of the crystallizer during solidification—and to avoid cracking or shell [...]

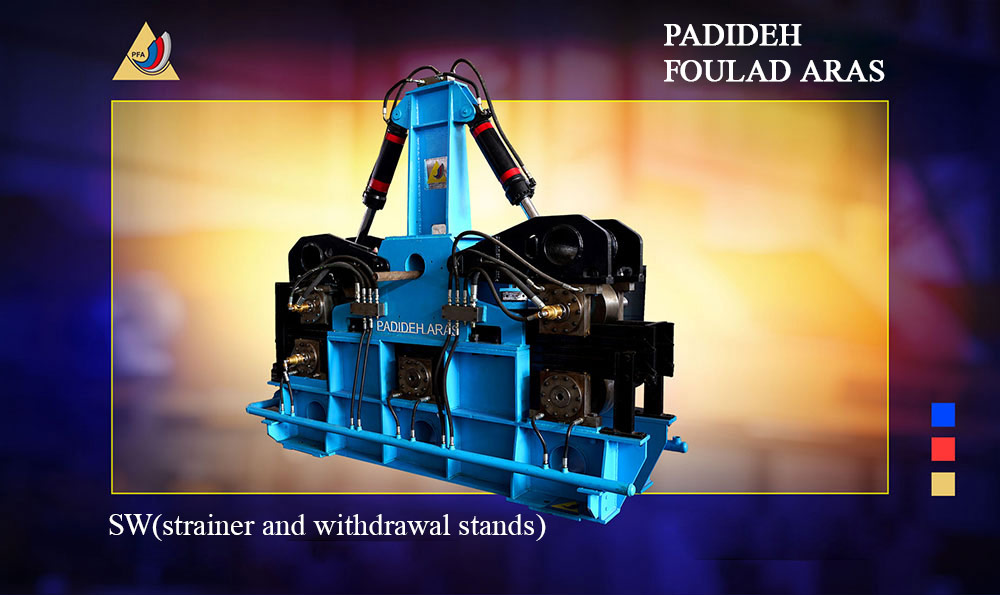

What is SW(strainer and withdrawal stands) ?

SW stretching device After leaving the mold and passing through the rollers of the cooling chamber, the billet is cooled by water sprinklers, and finally, it reaches under the stretching and smoothing rollers. {{ vc_btn: title=Download+Catalog&color=warning&link=url%3Ahttps%253A%252F%252Fpadideh-aras.com%252FCatalog-en%252FSW-en.pdf }}

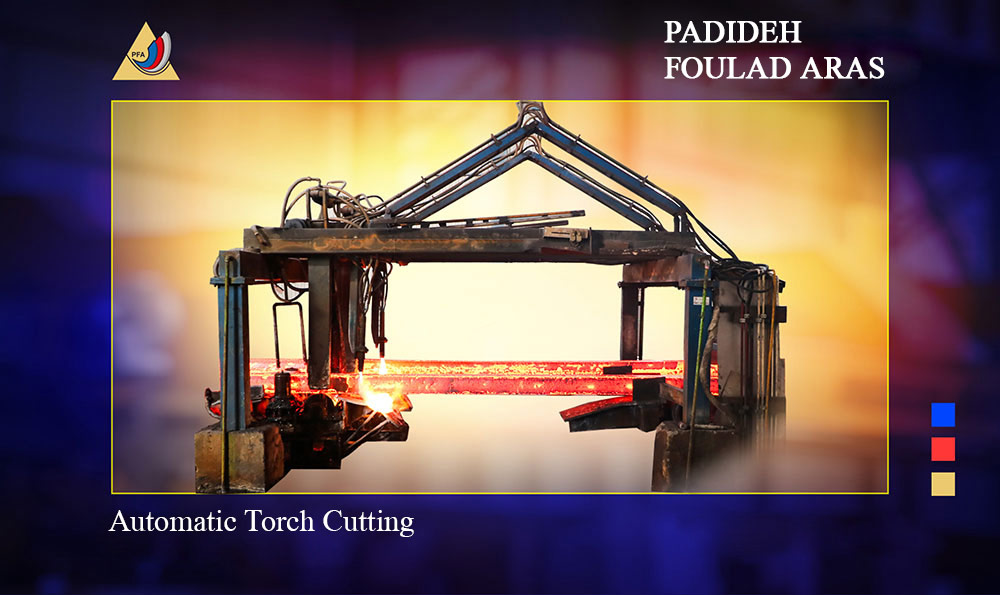

Automatic Cutting Machine for Continuous Casting Line

This machine is designed for the automatic cutting of billets and solid materials, delivering optimal performance. Its design and production have been carried out in full compliance with safety standards to minimize risks for personnel and facilitate operational efficiency. The system operates using a pneumatic clamping mechanism and is equipped with a cooling system. It [...]

Furnace Charging Wagon

Furnace Charging Wagon Furnace Charging Wagon The charging wagons manufactured by Padideh Foolad Aras Technical and Engineering Company are designed using advanced engineering software and carefully selected materials. During the production process, all initial material tests—including ultrasonic testing (UT) of round materials—are conducted. Furthermore, the welding process is rigorously monitored through detailed inspections, including UT [...]

Horizontal Ladle Preheater

Horizontal Ladle Preheater Preheating Ladles to Prevent Molten Temperature Drop In order to prevent a drop in the temperature of molten metal during the transfer and discharge into the ladle, the ladles are preheated to a temperature of approximately 1000-1100 degrees Celsius. Key Features: Automatic and safe control Uniform temperature distribution All equipment undergoes initial [...]

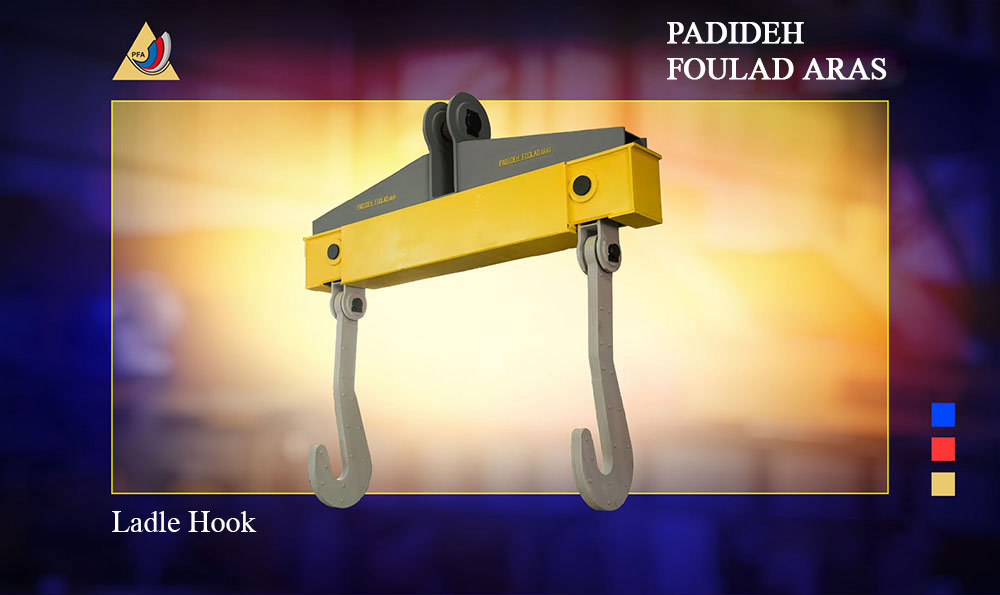

Ladle Hook

Ladle Hook Primarily used for connecting magnetic lifting devices to overhead cranes and gantry cranes in foundries and steel industries, such as for lifting molten metal ladles, slabs, billets, ingots, and long items like pipes and profiles. These devices are employed for lifting bulky equipment with specific dimensions and simultaneously lifting loads in cranes that [...]

Continuous Casting Machine (CCM)

The components of a Continuous Casting Machine (CCM) In order to convert molten metal into continuous cast billets, the molten metal is initially transferred via ladle and poured into the tundish. The tundish pours the molten metal through its nozzle into the mold, where the dimensions of the copper pipe inside the mold are selected [...]

Tundish

Tundish The tundish is used to direct molten metal into the mold and to distribute it across the predetermined number of strands. Located at the lower section of the tundish is the tundish nozzle. In continuous casting machines, the casting speed is determined by the internal diameter of the tundish nozzle and the level of [...]

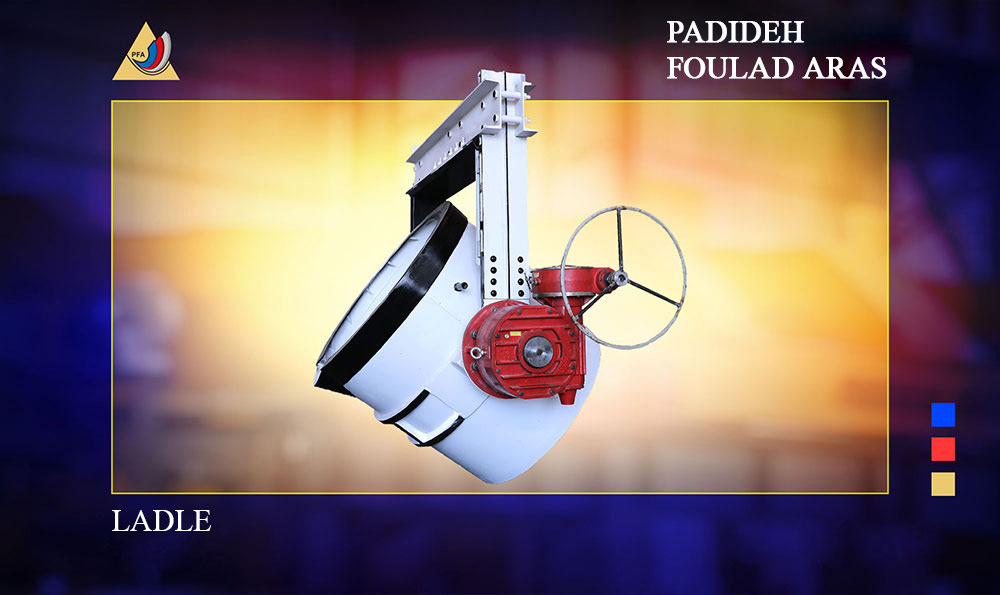

Top Pouring Ladle

Top Pouring Ladle The ladles designed by this company come in three types: overflow, T-pot, and bottom pour stopper, manufactured in various capacities for use in all steel and iron foundries. The ladle axles are made of CK-45 or MO 40 steel, providing the necessary strength and safety during molten metal transport. For ladles with [...]

Hydraulic Slag Breaker

Hydraulic Slag Breaker A hydraulic slag Hydraulic Slag Breaker is a device responsible for crushing the accumulated slag on the pusher lance. Additionally, slag is an artificial and by-product material that arises during the separation of iron in molten iron furnaces from impurities present in iron ore." {{ vc_btn: title=Download+Catalog&color=warning&link=url%3Ahttps%253A%252F%252Fpadideh-aras.com%252FCatalog-en%252FHydraulic-Slag-Breaker-en.pdf }}

Slide Gate System

Slide Gate System The sliding gate system has two types of operation: hydraulic and pneumatic. It plays a controlling role in the process of transferring molten materials from the ladle to the tundish. .The sliding gate system is installed in the lower part of the ladle {{ vc_btn: title=Download+Catalog&color=warning&link=url%3Ahttps%253A%252F%252Fpadideh-aras.com%252FCatalog-en%252FSlide-Git-en.pdf }}

Furnace Pusher

Furnace Pusher After charging sponge iron and forming a bridge on the molten surface, the furnace pusher creates a hole in the bridge and delivers its molten material to the surface of the sponge iron. This process ensures proper permeability of the molten material. On the other hand, gases produced from the melting process exit [...]